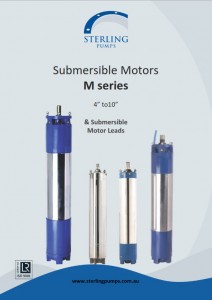

Submersible Motors; 6” 8” 10” – 5.5 to 185 kW

M Series

Sterling Pumps produce the M series range of quality submersible motors which offer a wide and versatile range of high efficiency and reliable operation in adverse conditions. Our submersible motors are water lubricated, are rewindable and feature Silicon Carbide mechanical seals as standard for durability and abrasive resistance offering longer in service life.

The M series motors are successfully installed and operated around the world in agricultural applications, such as crop irrigation, centre pivot supply, cattle watering and other more severe applications including mine dewatering, mineral processing, fire duty, offshore platform seawater lift, inline municipal boosting, water transfer, construction dewatering, breweries and other industrial processing.

Features

- 6” 5.5 kW to 45kW

- 8” 22kw to 110 kW

- 10” 55 kW to 185 kW

- Dual voltage/frequency 3 phase windings: 415V 50hz, 460V 60hz

- All rating sizes conform to NEMA shaft/spline/mount dimensions

- All 304SS construction, 6”

- 304SS and cast iron constructions, 8” and 10”

- 316SS constructions, 6”, 8” and 10”

- Silicon Carbide mechanical seal as standard

- Kingsbury style thrust bearings

- Water filled and lubricated

- Rewindable design

- Class E winding

- IP68 protection

- S1 continuous duty rated

- Maximum submerged depth of 350 metres

- Suitable for use with Variable Frequency Drives (VFD)

- Wide voltage parameters 415V -10%, +10%

- Motor protection: Ambient compensated thermal quick trip, Class 10 at x5 In, DIN 61947-4-1

- Water temperature up to 40°C without derating

- Suitable for potable water

Options

- 6 wire Star Delta windings available

- Larger size motors available up to 20” and 600kW

- Optional RTD’s and Pt100 can be installed

- Longer motor leads available

- 4 pole motors in 8”, 10”, 12” and 14” available

- High Voltages, 690V, 1,000V, 2,300V and 3,300V available

- High water temp up to 105°C and high voltages with PE2 windings

- 60 Hertz motors

- Special material constructions for 6” to 20”;

- 904 – Duplex Stainless steel, S2205

- Super Duplex Stainless Steel S2507

- Zeron 100

- Nickel Aluminium Bronze

- Copper Nickel CuNi 90/10

- Inconel 625

Specifications

6″ Motors

5.5 kW to 45kW

Standard construction is all 304SS

All 316SS construction

3 metre motor lead, 4C (3 wire & earth)

Motor diameter 144mm

30 starts per hour, max 1 min run time

0.20 m/s cooling flow required

415V ±10%, 3ph 50Hz 2 pole

8″ Motors

22 kW to 110kW

Standard construction is cast iron and 304SS

All 316SS construction

3 metre motor lead, up to 30kW, 4C (3 wire & earth)

5 metre motor lead, 37 to 110kW, 4C (3 wire & earth)

Motor diameter is 190mm

15 starts per hour, max 1 min run time

0.30 m/s cooling flow required, 22 kW to 37kW

0.45 m/s cooling flow required, 45 kW to 110 kW

415V ±10%, 3ph 50Hz 2 pole

10″ Motors

55 kW to 185kW

Standard construction is cast iron and 304SS

All 316SS construction

5 metre motor lead, 4C (3 wire & earth)

Motor diameter is 240mm

15 starts per hour, max 1 min run time

0.30 m/s cooling flow required, 55 kW to 93kW

0.50 m/s cooling flow required, 110 kW to 185 kW

415V ±10%, 3ph 50Hz 2 pole

Motor lead lengths are increasing

from 3 M up to 5 metres and 5 M up to 8 metres

over late 2017 into 2018