Testing, Repairs & Service

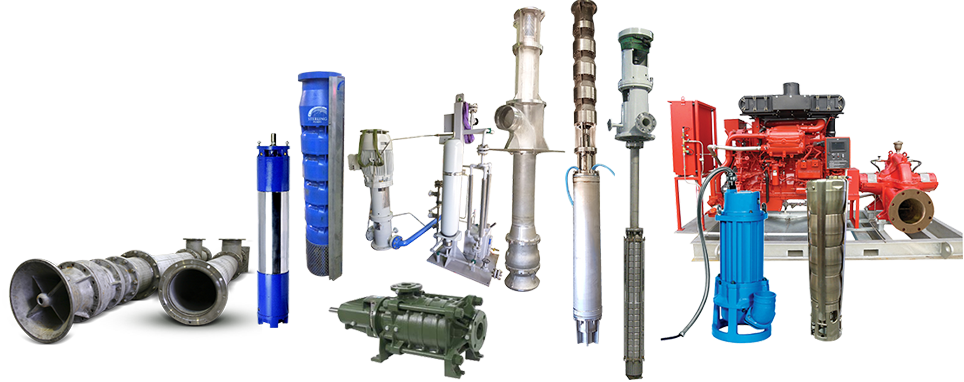

Sterling conducts all of its testing, service and repairs of vertical, horizontal split case, submersible, turbine pumps and motors at its facility in Pakenham, in the outer south eastern suburbs of Melbourne.

With our June 2020 acquisition of United Pumps also based in Melbourne, we have gained a 2nd larger pump testing facility that will further strengthen our testing capabilities.

Sterling is also able to dispatch qualified engineers for site inspections and commissioning as well as emergency repairs. We have staff who have current BOSIET and HUET certification for offshore platform work.

(BOSIET – Basic Offshore Safety Induction Education Training and HUET – Helicopter Underwater Escape Training)

A complete range of spare parts is maintained onsite to ensure that repair times can be kept to a minimum. We understand the importance of limiting costly downtime to our clients in oil, gas, fire-fighting, process and mining industries, among others.

Our facility combines a 10-tonne lifting capability and a multifunctional wet test area, with a team of highly experienced and qualified engineers, motor winders, machinists, fitters and welding staff.

Sterling repair all pump brands, and can reproduce components at our on-site machine shop as needed.

Sterling’s two testing facilities can handle most large capacity industrial pumps.

![]() TESTING Brochure_United_Sterling Pumps v07 2020

TESTING Brochure_United_Sterling Pumps v07 2020

Pakenham factory Testing Facility comprising:

- Flow loops from 50mm (2”) 5 m³/h up to 610mm (24”) 2,500 m³/h

- 100,000 litre above ground storage tank

- 50,000 litre underground storage tank

- 15 metre deep x 2.5 metre diameter well

- NATA certified equipment

- Ultrasonic flow meters

- Electronic data capture

- Testing to AS/ISO 9906:2018 (replaces AS 2147:2001 = ISO 9906:1999) and ISO 9906:2012

Sunshine factory Testing Facility comprising:

- 1,200 m2 floor test area

- Flows up to 1,700 m³/h and heads up to 1,800M

- Closed loop vacuum tank NPSH

- Power to 2.5MW

- NATA certified equipment

- Testing to AS/ISO 9906:2018 and API 610 (ISO 13709:2009) and other Standards