Bore irrigation accounts for up to 75 per cent of all energy usage on farms. With increasing energy costs, irrigators are looking for ways to reduce the energy usage of pumps to improve productivity and profitability. Here are the top five tips for irrigators to optimise the energy efficiency of their pumping system.

- Replace old pumps

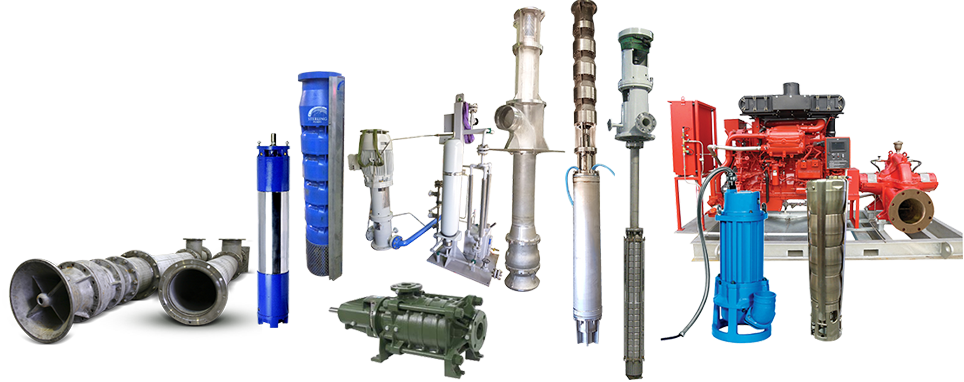

Like all machinery, pumps will lose energy efficiency as they age, with average losses of five to 15 per cent reported after 10 years of operation. While pumps have an average lifespan of 18 years before needing refurbishment or replacement, investing in new pumps will help irrigators pump the same amount of water using less energy.

Like all machinery, pumps will lose energy efficiency as they age, with average losses of five to 15 per cent reported after 10 years of operation. While pumps have an average lifespan of 18 years before needing refurbishment or replacement, investing in new pumps will help irrigators pump the same amount of water using less energy.

“Even if an old pump is in perfect working condition it will not be as energy efficient as a recent model. If you want to save on energy it’s worth investing in new pumps,” said Anton Merry, Managing Director at Sterling Pumps.

Mr Merry said there are a number of signs irrigators should be aware of that will indicate if a pump is not as energy efficient as it could be.

“If an irrigator has had a pump for a long time, one of the signs to look out for is a drop in flow. If they run a diesel pump they will also notice the pump needing to run at higher speeds to produce the same amount of water,” Mr Merry said.

- Use the correct pump for your system

Mr Merry said selecting the correct sized pump is important to ensure systems are operating with the least energy wastage.

“Selecting the right size pump for individual needs will not only ensure optimal energy efficiency but it will increase its lifespan and reliability,” Mr Merry said.

One of the main problems that occurs during pump selection is the overestimation of pump duties during the design stage of an irrigation scheme, which can lead to oversized pumps.

“Not only are larger pumps more expensive to install, if they are too big for the individual application they will consume more energy than is necessary and will need frequent maintenance,” Mr Merry said.

There are five signs that irrigators can look for if they think they may have oversized pumps:

- Increased flow noise

- Highly throttled flow control valves

- Excessive use of bypass lines

- Frequent replacement of bearings and seals

- Intermittent pump operation

Undersized pumps can be just as problematic as they reduce a system’s water efficiency.

- Regular maintenance

Pumps have a number of moving parts which deteriorate over time due to increased friction from dirt and particle build-up, cavitation from high water pressure, and other wear and tear. Pump components can also become misaligned with use.

Ensuring regular maintenance is performed on irrigation pumps will ensure optimal energy efficiency and increase longevity.

“Regular pump maintenance is also important for operating efficiency and the early detection of problems. It ensures they are repaired before efficiency and capacity are lost, and pump failure occurs,” Mr Merry said.

- Improperly sized or designed fittings

Improperly sized or designed fittings can also impact the overall energy efficiency of a pump.

For example, impellers are usually available from manufacturers in a variety of sizes, but if an improperly sized impeller is installed the efficiency is compromised.

“Oversized impellers cause excessive energy consumption due to excessive head,” Mr Merry said.

“However, undersized impellers are also problematic as pump efficiency decreases due to reticulation within the pump.

“When choosing or trimming an impeller it is important that it matches the requirements of the application to help the pump reach its best efficiency point (BEP). A correctly sized impeller can improve energy efficiency on average by 10 per cent.”

- Energy source

Traditionally, pumps are powered by diesel or electrical energy supplied from the grid.

Diesel is the ideal energy source for irrigators in remote locations who are unable to connect to the electrical grid, however it is less energy efficient than electric pumps and require more maintenance.

Mr Merry said there is now a third option available to irrigators that can provide a lower cost alternative in the long-term.

“Solar pumps are an ideal alternative for irrigators who are wanting a more efficient way to run their systems.

“In the past, solar pumps were expensive but a major increase in buyers has seen the cost become more affordable,” Mr Merry said.

Mr Merry said solar can be integrated with diesel or electricity to maintain a constant supply of power when there is limited sun exposure.

“While solar is unable to work at night and at times when there is less sun, it still saves irrigators money and reduces the pressures of rising energy costs.

“For irrigators operating diesel pumps, it can also reduce the amount of maintenance required when operating diesel all the time.”