With the increasing costs associated with manufacturing in Australia, many pumps are being shipped from overseas for use by local irrigators. But the country’s strong irrigation industry is crying out for local pumps and the knowledge and trust that comes with them.

With the increasing costs associated with manufacturing in Australia, many pumps are being shipped from overseas for use by local irrigators. But the country’s strong irrigation industry is crying out for local pumps and the knowledge and trust that comes with them.

Advances in Australian pump manufacturing have increased the efficiency and lowered the running costs of irrigation pumps by looking at the specific pumping and installation requirements of local systems and regions.

Victorian-based pump manufacturer Sterling Pumps believes that having a strong manufacturing base in Australia and acquiring the knowledge of local irrigators is key to a successful industry.

Sterling has now welcomed New South Wales pump company Ausmec and Victorian company Deps into its organisation, providing a bigger supply of local pumps for irrigators and carrying on the legacy and knowledge of these heritage companies.

Sterling Pumps Managing Director Anton Merry said having expertise on specific irrigation areas across the country helps them to provide standard and custom-designed pumps that will increase system efficiency.

“Peter Ryrie, the founder of Ausmec, understands the pumping requirements of the NSW Riverina and what pumps are best suited to this region’s irrigation bores, while Deps have smaller vertical turbine pumps perfect for Australian water well bores.

“We’re using the local knowledge of these two companies and combining it with our modern technology so customers can be confident that their system will pump more water and decrease running costs based on their needs,” Mr Merry said.

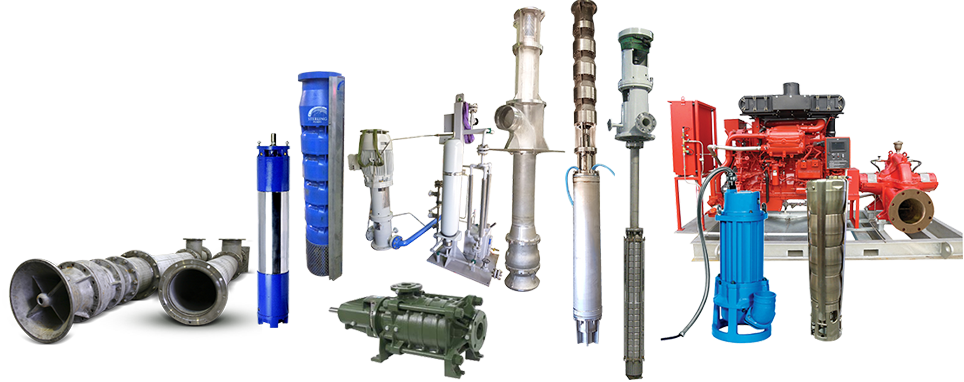

Ausmec and Deps have been key players in Australia’s irrigation sector for the last 50 years and their pumps are now merged with Sterling’s already extensive range of irrigation and drainage pumps.

Mr Merry said the automation of manufacturing in Australia is one of the key factors that has resulted in keeping prices down and improving pump quality.

Mr Merry said the automation of manufacturing in Australia is one of the key factors that has resulted in keeping prices down and improving pump quality.

“3D modelling of components and pump units, computerised manufacturing control and CNS mass manufacturer of components has all led to a higher quality, better finished and lower cost product that is increasing the overall installation efficiency and life of products,” Mr Merry said.

“We’re using these manufacturing improvements alongside a solid understanding of the Australian pump landscape to support the local industry.”

Irrigator Peter Ryrie introduced a high-efficiency vertical turbine pump into the NSW Riverina area, which Sterling now supplies with the windows range of low head axial and mixed flow irrigation and drainage pumps.

Mr Ryrie has seen many changes to Australia’s irrigation industry over his career, with the decline of local manufacturing, he said, causing the most concern.

“Manufacturing in Australia has unfortunately become limited but it’s terribly important that we keep our foundries going and keep manufacturing the equipment that best suits our needs in Australia.”

While now retired, Mr Ryrie is enthusiastic that the work he has done and his irrigation knowledge will continue to be improved upon at Sterling and used to offer solutions for all irrigators.

“Over all the years I’ve been involved with pumps and lots of pump people but to me Sterling is the brightest on the horizon, not only because of their performance, but how many pump companies out there are flying the Australian flag?

“They are concentrating on the efficiency of pump design and the right selection of materials to give long lasting service, lower running costs and create the most efficient overall design.”

Mr Ryrie’s vertical turbine pump patterns came from an increasing demand for bores and pumps in the 1960s, with the cost of larger bores and pumps becoming a major investment that was justified by the certainty of production.

“In these days, efficient design of the irrigation layout, recirculation of tailwater and on-farm storage became the norm,” Mr Ryrie said.

“Greater efficiency of installation and management also became an urgent necessity to offset the rising cost of fuel and electricity.

“These principles still apply to the industry today and so having a pump with a strong historic design, coupled with new technology and also manufactured in Australia is important.”

“These principles still apply to the industry today and so having a pump with a strong historic design, coupled with new technology and also manufactured in Australia is important.”

Mr Merry said that having ties to local manufacturing also gives users of specific pumps assurance that spare parts are also going to be readily available.

“A lot of irrigators are using pumps that are specific to the Australian market, so they need to have parts available.

“A big issue in our pump industry is the high cost of spare parts and the long lead times, so we’ve committed to having a large range of parts available for stock,” Mr Merry said.

While Sterling has a deep history rooted in Australia’s irrigation industry, through companies like Ausmec and Deps, it also has strong connections to pump networks all of the world through WPIL.

Sterling is part of the global WPIL International group alongside WPIL India, Mathers in the United Kingdom, APE Pumps in South Africa, Aturia, Rotos and Mirelli in Italy and Rutschi Pumps in France.

These companies are leaders in submersible and vertical turbine pumps in their respective countries and Mr Merry says through their relationship with Sterling, they can share information and technology.

“This group has a common technology base and a very strong commitment to manufacturing in each area, so our products are strengthened by each other.

“We share technology information and combine this with our local expertise to manufacture better, more efficient pumps for agriculture and the irrigation industry.”